In today’s fast-paced industrial landscape, precision is paramount. Enter laser cutting services in London – the pinnacle of modern manufacturing technology. Laser cutting and CNC cutting services offer a myriad of advantages, from unparalleled accuracy to versatility across materials, making them indispensable in various industries.

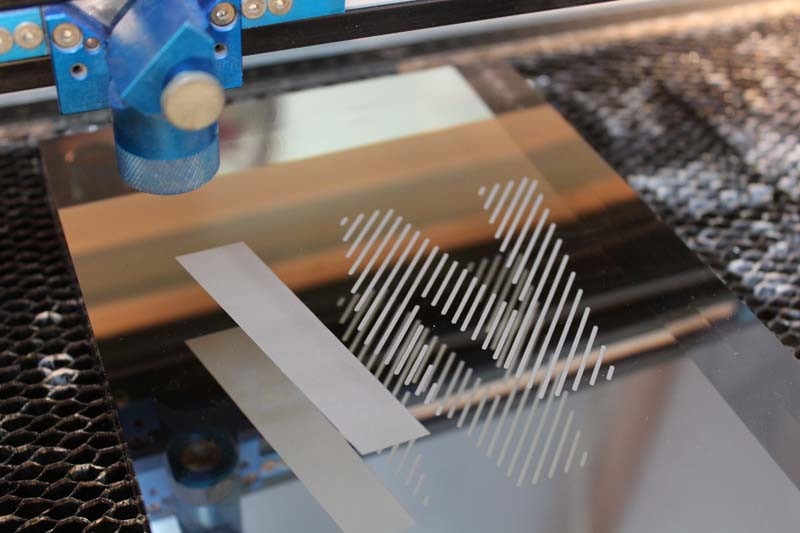

Precision Redefined: At the heart of laser cutting services lies a laser beam of extraordinary precision. Guided by advanced computer systems, this beam can make cuts with micron-level accuracy, ensuring that even the most intricate designs are executed flawlessly. Whether it’s intricate components for aerospace applications or finely detailed architectural elements, laser cutting services deliver precision beyond compare.

Versatility Across Materials: One of the most significant advantages of laser cutting services is their ability to work with a diverse range of materials. From metals like stainless steel and aluminum to non-metals such as wood, plastics, and even ceramics, laser cutting services can handle them all. This versatility opens up endless possibilities for designers and manufacturers, allowing for the creation of products that were once thought impossible.

Efficiency and Speed: Laser cutting services excel in efficiency, enabling rapid production of parts and components. The laser beam moves swiftly over the material, completing cuts in a fraction of the time required by traditional methods. This accelerated production not only enhances productivity but also reduces lead times, giving businesses a competitive edge in today’s market.

Customization and Prototyping: Laser cutting services offer unparalleled flexibility for customization and prototyping. Whether it’s creating personalized products for consumers or iterating on design concepts, laser cutting allows designers and manufacturers to experiment with different ideas quickly and cost-effectively. This agility is essential in industries where innovation and adaptability are key to success.

Sustainability and Minimal Waste: In addition to precision and efficiency, laser cutting and CNC cutting services are also environmentally friendly. By minimizing material waste and optimizing material usage, laser cutting services contribute to sustainability in manufacturing processes. Less waste means fewer resources consumed and a smaller environmental footprint, making laser cutting services a responsible choice for businesses looking to reduce their impact on the planet.

Original Source: Laser Cutting Services in London